Research, material analysis, and prototyping are among the activities undertaken as part of project and product development, both directly designed by Plus Biomedicals and in consultancy for third parties, following a process certified under the international standard ISO 13485.

The flagship of Plus Biomedicals is the Research & Development department, where, by the transversality of the skills and the flexibility of the process, projects are also developed on a tailor-made basis, for even “niche” needs and for very narrow targets, which would not find ad hoc solutions on the market.

Here, projects are born and solutions for neurorehabilitation are developed, but innovations are also elaborated and tested to facilitate the everyday life of able-bodied people, with a view to continuous research evolution.

Do you have a project in the medical field and want to realize it?

At Plus Biomedicals, you will find the perfect team of professionals and a dedicated instrumental department to bring it to life.

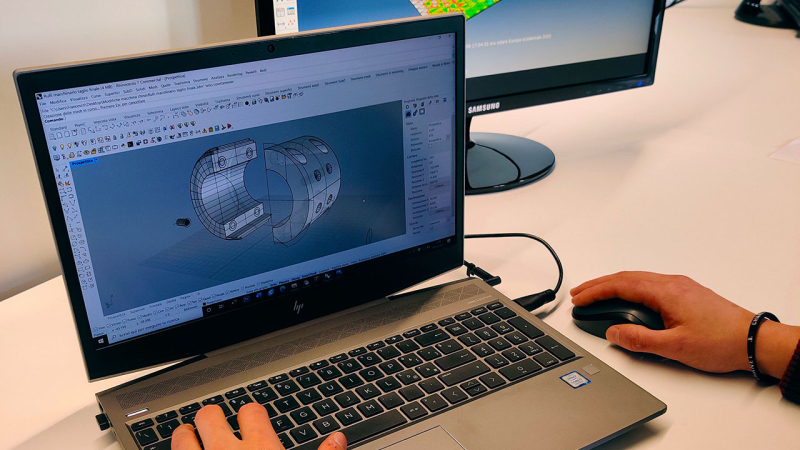

3D design and modeling with FEA analysis

In the area of design, through the use of 3D software, the team models any type of geometry to make any design real. It also carries out studies with simulation software and Fea analysis, a computer simulation technique used in engineering analysis, which is applied to already designed components or products to validate their functionality and, through reverse engineering analysis, also to existing components or products to improve their features.

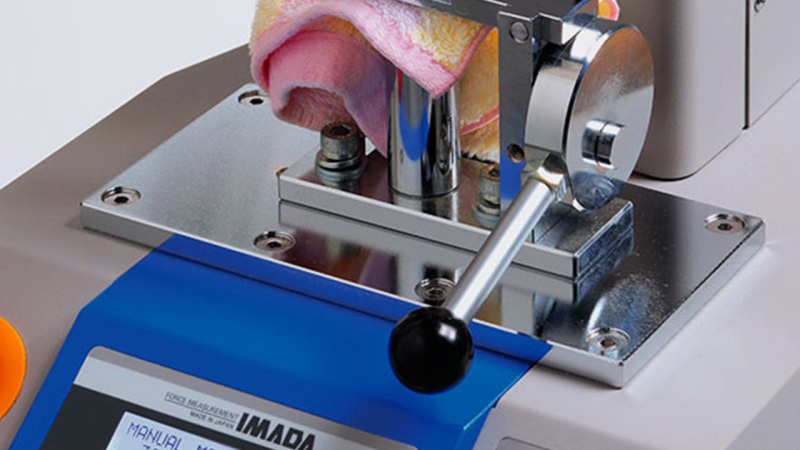

The best materials for bringing every idea to life

For the mechanical characterization of materials, Plus Biomedicals studies the most suitable materials for the realization of each idea thanks in part to in-house instrumentation that allows for the analysis of the tensile and compressive mechanical strength of the materials and, therefore, a better assessment of performance capabilities.

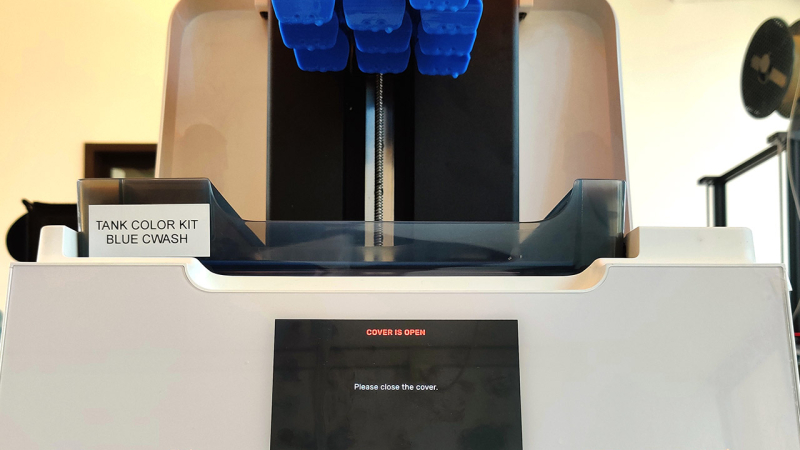

Realization of qualitaive and fuctional prototype

The R&D department can make rapid prototypes of designs to fully evaluate actual functionality and improve features. In addition to the team’s expertise, crucial is the instrumentation, which includes 3D printers with FDM technology, to make robust, durable, and dimensionally stable parts with the highest degree of accuracy and repeatability compared to any other 3D printing technology.

In addition, Plus Biomedicals uses SLA technology, which makes it possible to produce parts with complex geometries and better surface finishes than other additive processes.

Plus Biomedicals team is always monitoring, researching, and identifying cutting-edge and innovative technologies to produce each product while meeting design expectations.